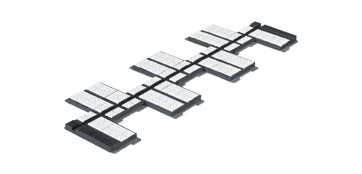

Flex-Lag® Weld-On™ Pulley Lagging

Flex-Lag® Weld-On™ Pulley Lagging features a patented gear-tooth design. This eliminates the wide gutters present in conventional weld-on lagging products and also helps minimize problems associated with vibration, cleaner chatter, and overall belt cleaner compatibility.

Flex-Lag® Weld-On™ Pulley Lagging features a patented gear-tooth design. This eliminates the wide gutters present in conventional weld-on lagging products and also helps minimize problems associated with vibration, cleaner chatter, and overall belt cleaner compatibility.

- Available in rubber and ceramic

- Pre-cut to standard CEMA pulley widths for fast, easy installation

- Can be easily installed without removing the pulley

- Available with FRAS-approved rubber

How to Select the Right Lagging Product

To select the right pulley lagging, be sure to consider the environmental conditions around the pulley:

- Belt condition, i.e., wet or dry

- The service required for bonded lagging versus weld-on

- The expected wear life of the lagging

|

Flex-Lag® Rubber |

Flex-Lag® Ceramic |

Flex-Lag® Weld-On™ |

||||||

|

Criteria |

Light Duty |

Plain |

Diamond |

Diamond Pattern |

Medium Ceramic |

Full Ceramic |

Rubber Diamond |

Full Ceramic |

|

Thickness Range Available* |

7.5 mm |

10-25 mm |

10-30 mm |

12-30 mm |

12-30 mm |

12-30 mm |

15 mm |

15 mm |

|

Belt Width* |

Any Width |

Any Width |

Any Width |

Any Width |

450-3000 mm |

450-3200 mm |

450-3200 mm |

450-3200 mm |

|

Minimum Pulley Diameter |

50 mm |

300 mm |

300 mm |

300 mm |

300 mm |

300 mm |

400 mm |

400 mm |

|

Dry Friction |

Very Good |

Excellent |

Very Good |

Very Good |

Excellent |

Excellent |

Very Good |

Excellent |

|

Wet Friction |

Average |

Average |

Good |

Very Good |

Excellent |

Excellent |

Good |

Excellent |

|

Wet/Muddy Friction |

- |

Average |

Very Good |

Very Good |

Very Good |

Very Good |

Very Good |

Very Good |

|

Wear Life |

Good |

Good |

Good |

Very Good |

Excellent |

Best |

Good |

Best |

|

Ease of Installation |

Good |

Good |

Good |

Good |

Good |

Good |

Best |

Best |

|

Drainage Grooves |

No |

Yes |

||||||

|

FRAS (Fire Resistant Anti-Static) |

No |

Available |

||||||

|

Rubber Compound |

SBR |

|||||||

|

Hardness (Shore A) |

68 +/- 3 |

|||||||

|

Ceramic Compound |

- |

- |

- |

Al2O3 |

Al2O3 |

Al2O3 |

- |

Al2O3 |

|

Ceramic Coverage |

- |

- |

- |

13% |

39% |

80% |

- |

74% |

|

Can be used in an autoclave (with application of uncured rubber) |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

No |

No |

|

Operating Temperature |

-15° - 85° C |

|||||||

|

COF Values |

Ask Your Local Sales Representative |

|||||||

*Additional thicknesses and widths available as special orders.

Flex-Lag® Weld-On™ Rubber Lagging

- Performs well in both dry and wet applications

- Available in SBR rubber and FRAS-approved rubber

- Belt Width: 18" - 72"

(450 - 1800 mm)

Flex-Lag® Weld-On™ Ceramic Lagging

- Most consistant performance in dry, wet, or muddy applications

- 74% ceramic tile coverage

- Available in SBR rubber and FRAS-approved rubber

- Belt Width: 18" - 72"

(450 - 1800 mm)

Resources

Flex-Lag® Weld-On™ Lagging Installation Video

Flex-Lag® Weld-On™ Pulley Lagging Sell Sheet

MINELINE®

When standard products just won't do.

Flexco Mineline® products are designed and engineered to work in some of the toughest applications in the world that test the strength and durability of your conveyor system. Products carrying the Mineline® name are proven to work — even where other products have failed.