Frequently Asked Questions

How do I determine the best cleat pattern, height, and spacing?

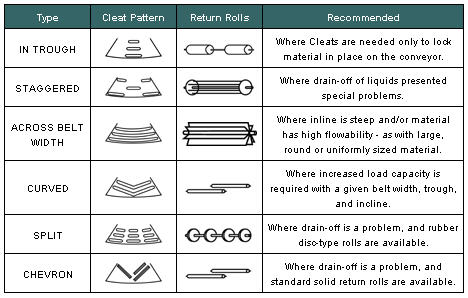

Cleat Patterns

When choosing cleat installation patterns, you should give major consideration to the type of return support available or feasible. Where conveyor pulley center distances are 15 feet or less, it is often possible to omit return rolls safely. Where the curved or chevron pattern is used with standard return rolls, cleats should be arranged so that they provide a set of continuous contacts between cleats and rolls. On drives using pulleys less than 6" in diameter, curved or chevron patterns should not be used. The ends of cleats mounted in a curved pattern should be tapered to lead smoothly onto the return rolls.

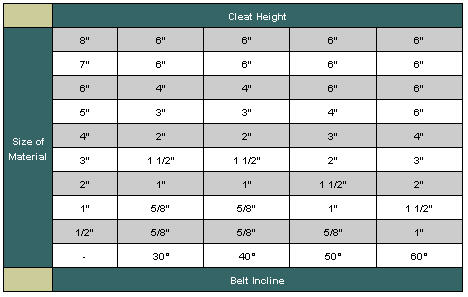

Suggested minimum cleat height for various sized materials and degrees of incline

This chart assumes that material being conveyed has a 30° natural angle of repose. For rounded or free-flowing materials with a natural angle of repose of less than 30°, use the cleat corresponding to the next higher material size. (For example, if your materials is 4" high, with a natural angle of repose of less than 30°, and your belt incline is 40°, you would use a 3" cleat - that is, the cleat size corresponding to 5" material.)

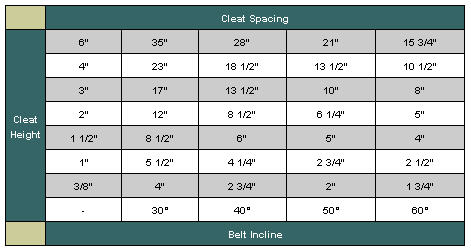

Suggested cleat spacing

This chart assumes that material being conveyed has a 20° dynamic natural angle of repose (30° natural angle of repose) and that cleats are installed at a right angle to the belt edge. For more free-flowing material, use slightly closer cleat spacing.