When Is It Time to Use a Finger-Over-Finger Endless Splice?

Choosing an endless splice configuration is an important decision when it comes to maximizing splice performance and longevity on your conveyor belt. Several factors should be taken into consideration when selecting the best splice for your application, including: belt construction, splice strength, conveyor design, application requirements, and commercial factors.

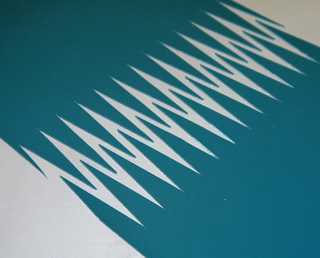

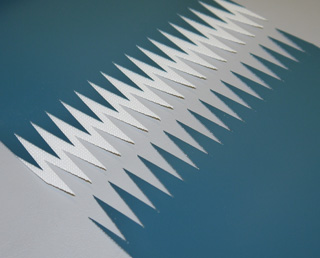

Oftentimes, Finger splices are used because they can be completed more quickly. Finger splices are also popular because they are the only type of endless splice that does not increase the splice thickness of single-ply belts. If a belt has multiple plies, a Finger-Over-Finger splice is often recommended. And sometimes, the decision stops there.

After all, in many light duty applications, the product being conveyed is quite light. Initially it may seem that the Finger splice will provide adequate strength for your light duty application, but what should you be aware of when trying to decide what splice will work with your system?

|

|

| Finger Splice | Finger-Over-Finger Splice |

How Conveyor Design Affects Your Endless Splice

Some conveyor designs have features which may make the Finger-Over-Finger splice a better choice. The primary difference between the Finger Splice and Finger-Over-Finger splice is that the Finger-Over-Finger splice has two layers of finger splices slightly offset from each other. This built-in step provides an additional barrier to forces wanting to push through the belt. Some conveyor designs where the Finger-Over-Finger splice may be advantageous are:

- Conveyor belts with a V-guide installed – As the splice wraps the conveyor pulleys, extra tension at the V-guide can force the V-guide through the fingers of a Finger splice. This same force is further exaggerated where belts are mistracking and the V-guide migrates out of the groove. The overlap of the Finger-Over-Finger splice reduces the probability that a V-guide will contribute to premature splice failure.

- Conveyors with Segmented Transfer Rollers – Segmented Transfer Rollers are commonly used in higher-tension applications where small diameter rollers are required for transferring product. The construction of many segmented rollers often creates isolated areas of increased tension across the belt width. These isolated, higher-tension areas often cause the single fingers of the Finger splice to be forced open. The step of the Finger-Over-Finger splice reduces the possibility that the higher tension areas can force open a finger.

Product Builds Up Under the Conveyor Belt

Many times, a belt is used for conveying or processing bulk products. Bulk products will commonly migrate inside conveyors and get lodged between the belt and the slider deck and/or rollers. Dough and chocolate transport applications are notorious for product build-up on conveyor rollers and pulleys. As with V-guides, these situations create areas of increased tension that are more likely to push through a Finger splice than the offset fingers of a Finger-Over-Finger splice.

Impact on Conveyor Belt

Belt impact can be found in applications involving forces on a belt that occur when small, heavy products are dropped onto the belt. The localized impact of some of these processes can affect individual fingers. Because the fingers of the Finger splice are cut entirely through the belt, the impacted finger is only supported along the edges. In contrast, the impacted finger of the Finger-Over-Finger is supported by overlapping the fabric below. In these applications, a Finger-Over-Finger splice is preferred.

Other Endless Splicing Considerations

There are commercial factors to take into consideration as well. The Finger-Over-Finger splice requires the additional process of ply separation and punching fingers in two layers. The additional process requires some additional time, which does cost money. So the performance benefits of the Finger-Over-Finger splice must be evaluated against the additional cost of fabrication.

Endless Splice Strength

Finally, did you know the strength of the endless splice is directly related to the amount of bonding surface in the splice? With the Finger splice, the bond strength is limited to the single linear bonding line of the fingers. The linear bonding is based on the length and width of the finger, so the longer the bonding line, the stronger the splice.

For example: The linear bond of an 80 mm long finger by 20 mm wide is stronger than a 50 mm long finger by 20 mm wide. With a single ply belt, the user increases the linear bond through longer and/or narrower fingers.

If the conveyor belt has multiple plies, then the user will typically consider a Finger-Over-Finger splice. The Finger-Over-Finger splice is created by separating the plies and punching fingers on the two layers on an overlap. This allows for two linear bonds in addition to the bond between the offset layers. Typical Finger-Over-Finger splices will be considerably stronger than standard Finger splice of the same belt material.

Which Splice is Right for You?

In the end, your choice of endless splicing process depends on the needs of your individual application. Take into account your belt type, conveyor, and product, and make the best decision based on your circumstances.

Authored by: Michelle Graves, Product Manager

Graves manages the overall global business, market plans, technical support, and activities associated with the light-duty belting market for the Novitool® product line, including new product development, market analysis, and global strategy. Graves holds a bachelor’s degree from Albion College as well as a master’s degree from Grand Valley State University.

Subscribe to the Flexco Blog

Published Date

October 04, 2018Product Group

- Endless Splicing Systems

Issues

- Downtime

- Maintenance