Segmented Transfer Plates Close Gap for Midwest Parcel Facility

Industry

Parcel

Application

Mainline conveyor

Product

Segmented Transfer Plates

Objective

Create safe transfers

Eliminate package damage

Conveyor Detail

48" wide, 2 ply carcass belt

Problem:

A major parcel handler has two different styles of draw bridge transfers at its Midwest facility. The first one pivots at the shaft of the tail pulley and the second one pivots approximately 16" in front of the tail pulley. Both used a standard UHMW black plate to fill the gap at the head and tail pulleys. The distance between the conveyors can range in lengths, but the average is approximately 7". The gap between the belt and UHMW transfer plate was usually 1/4" to 3/8" at these transfers. This oversized gap allowed packages, mailers, labels, and even an automotive tire to slide under the transfer plate. The gap had also become an extensive safety risk within the facility because the line operators have a tendency to disregard safety regulations to reach into the conveyor in an attempt to extract the items that get stuck. Using a UHMW transfer plate that was fitted any tighter would cause the plate to pinch the belt when the drawbridge was lifted.

Solution:

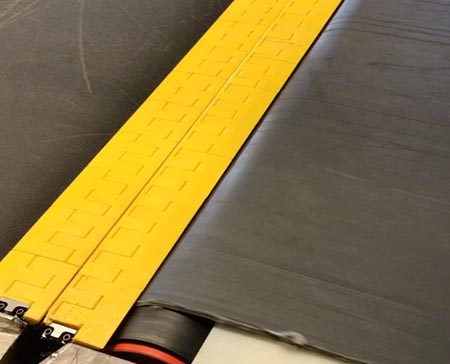

With the introduction of the new Segmented Transfer Plate, Flexco was able create a totally custom solution using two separate sets of transfer plate bars. The first is a 3" Segmented Transfer Plate, including a 2" segment opposite the 1" bridge segment ; the second is a 4" Segmented Transfer Plate made up of 2" x 2" segments. The 4" Segmented Transfer Plate was fastened to the stationary conveyor, and the 3" Segmented Transfer Plate was attached to the bridge conveyor. The 3" Segmented Plate’s bridge segment moves under the 4" Segmented Transfer Plate when the drawbridge conveyor raises and fits tightly against the stationary 4" Segmented Transfer Plate when the drawbridge is lowered due to some slight modifications made during the installation process.

Result:

Thanks to the installed Segmented Transfer Plate, a functioning transfer between the drawbridge and stationary conveyor, with a paper-thin gap between the belt and new transfer plates, has been attained. As an added bonus, the new transfers are manufactured in safety yellow, a huge benefit seen by the maintenance managers. This minimal gap stops packages and other items from going between the plates and the belt and reduces the risk of operators reaching into the moving conveyor.