FGP Food Grade Precleaner Generates a $9,000 Annual ROI for Major Bakery in UK

Industry

Industrial Baking

Application

Cereal snack bar line

Product

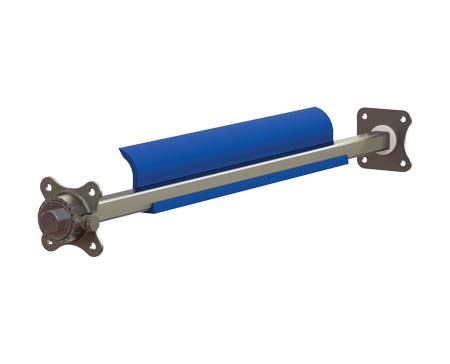

FGP Food Grade Precleaner

Objective

Reduce carryback

Eliminate belt damage

Reduce maintenance costs

Conveyor Detail

2-ply polyurethane food grade belting

Problem:

Carryback, or product that adheres to the belt, was a big problem for a major industrial baking operation in the UK. The carryback from the snack bars was damaging the belt, as well as causing endless splices to fail, requiring emergency visits from splice crews. With an average downtime cost of approximately $10,000 USD an hour, on top of the fee required to bring a vulcanizing crew out, the operation was desperate for a change.

Solution:

After discussing the problem with a local distributor, the operation’s development engineer was introduced to the FGP Food Grade Precleaner from Flexco. The Flexco FGP Food Grade Precleaner was attractive to them because of its ease of installation and quick disassembly and reassembly for cleaning and sanitation. The food-grade, metal detectable UHMW blade and stainless steel components were also a plus for an operation with stringent sanitation requirements.

Result:

The installation of the FGP Food Grade Precleaner significantly reduced the belt damage being caused by the carryback. It also allowed the maintenance crew to focus on proactively splicing belts during scheduled downtimes instead of bringing in an emergency crew to do so. The company estimates an almost $9,000 USD annual return on investment because they are not buying new belts and paying to have them installed as they had in the past.